RAS

il filtro che ha fatto la storia di FIMIC

RAS è il cambiafiltro automatico e autopulente FIMIC progettato per adattarsi perfettamente alle tue esigenze.

Configurabile in base al materiale da trattare, alla produzione oraria, al livello di contaminazione e al grado di filtrazione desiderato, è il prodotto più conosciuto di Fimic, ancora oggi simbolo di una tecnologia che ci ha resi un punto di riferimento internazionale.

Con oltre 600 unità installate in tutti i continenti – dal Sudamerica alla Nuova Zelanda – RAS rappresenta un successo e una conferma del valore del made in Italy nel riciclo dei materiali plastici.

Ogni dettaglio conta.

RAS si distingue per un sistema di raschiamento automatico che lavora senza interruzioni, mantenendo costante la qualità del filtraggio.

Ogni componente è pensata per durare nel tempo, semplificare la manutenzione e ridurre i fermi impianto.

Breaker 45 mm supporto principale della pressione melt e del filtro.

Breaker speciale 8 mm: aumenta la superficie di filtrazione per filtrazioni fini.

Filtro forato laser o punzonato: disponibile in diverse misure per adattarsi alle esigenze specifiche.

Porta raschietti FIMIC: il cuore del cambiafiltro, garantisce l'efficienza del processo di raschiamento.

Qual è il filtro giusto per te?

Scegliere il filtro corretto significa ottenere il massimo dal tuo processo di riciclo.

Visualizza chiaramente la differenza tra le opzioni disponibili.

Filtrazione da 60 a 300 micron.

filtrazione da 400 a 2000 micron

Dimensioni filtro

- Ø325mm – 779cm²

- Ø400mm – 1206cm²

- Ø500mm – 1912cm²

- Ø600mm – 2776cm²

- Ø700mm – 3796cm²

- Ø800mm – 4945.5cm²

Come funziona RAS?

Due lame interne raschiano la contaminazione trattenuta dal filtro, mentre il portalame la raccoglie e la convoglia verso l’uscita.

Una volta completato il ciclo, il materiale contaminato viene scaricato automaticamente attraverso la valvola frontale.

Il sistema può funzionare in due modalità:

Quando la pressione impostata viene raggiunta, il portalame inizia a ruotare alla velocità desiderata, raccoglie la contaminazione e apre la valvola solo al termine del giro completo, garantendo un’operazione pulita ed efficace.

Continua

In caso di contaminazione elevata, il portalame può ruotare costantemente a bassa velocità, mentre la valvola frontale si apre solo quando necessario, grazie a un temporizzatore che gestisce gli intervalli di scarico.

Scopri le caratteristiche che hanno fatto di RAS il prodotto più venduto in tutto il mondo.

L’interfaccia touch screen è intuitiva e l’intero processo è automatizzato.

Ogni RAS integra un codice QR che ti collega direttamente a video tutorial dettagliati, per intervenire rapidamente e senza errori.

Magazzino automatizzato con spedizioni in 24 ore.

Adattiamo ogni RAS alle reali esigenze produttive del tuo impianto: tipo di plastica, contaminanti, portate, micron, quantità da lavorare.

RAS è progettato per funzionare da solo. Non ti resta che avviarlo!

Guarda com’era prima

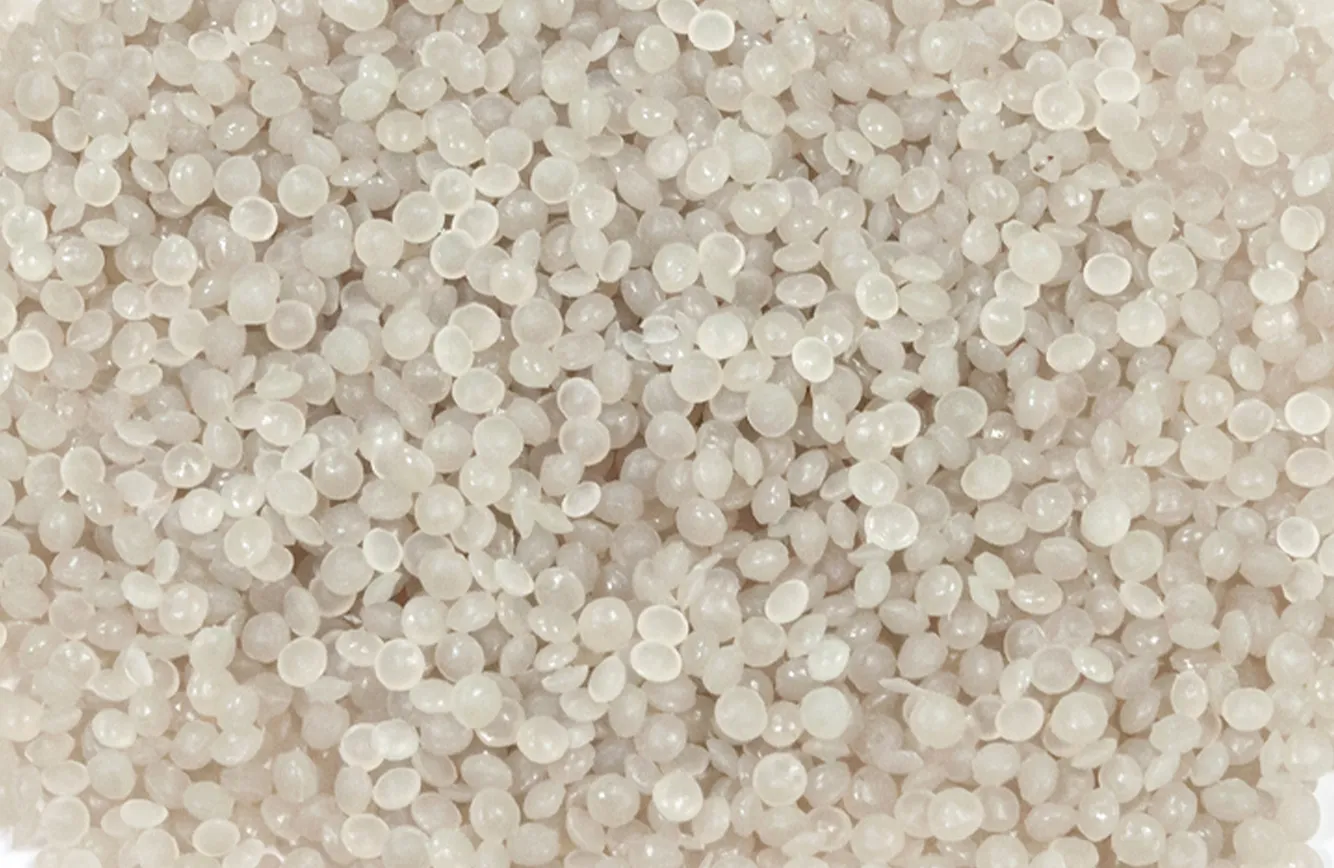

Perché un buon risultato non si vede semplicemente.

Si tocca, si misura, si pesa.