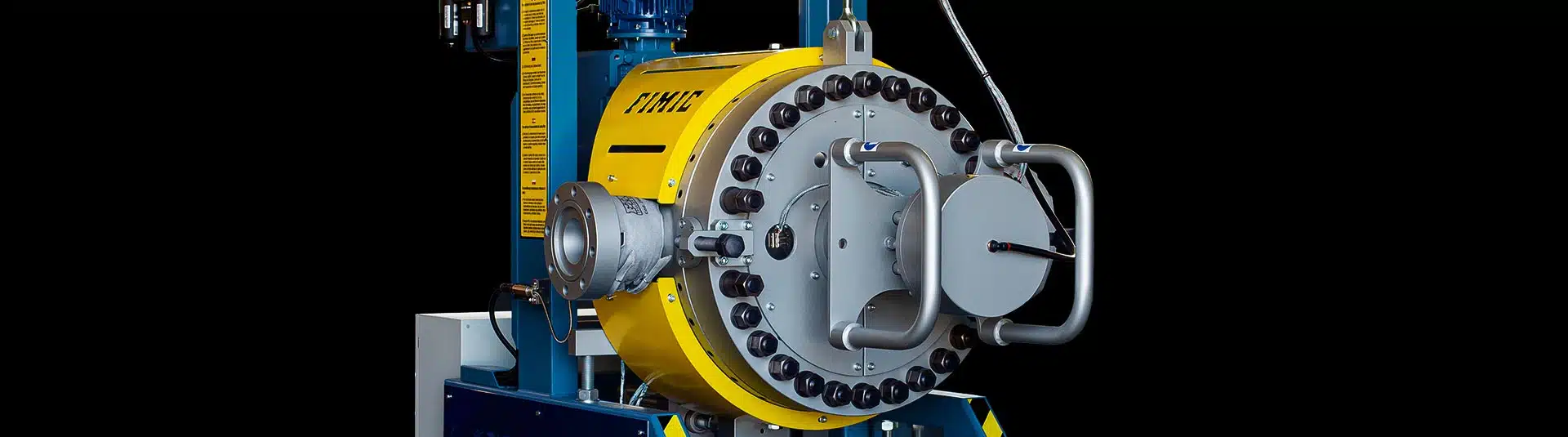

GEM

The widest filtration surface in the world

GEM is the FIMIC automatic melt filter designed for those who need a larger filtration surface and high performance, even with extremely contaminated materials, using only two screens.

It combines the proven technology of RAS with the power of the double filter ERA, ensuring continuous operation and purity of the processed material.

With its two parallel and independent chambers, it is the ideal filter for high-throughput production.

Durable, precise, tireless.

Exactly what your results deserve.

Designed for high throughput. Built to keep running.

In plastic recycling, the volume of materials to be processed grows every day.

And so does the demand for quality, continuity, and efficiency.

That’s why we developed GEM: the automatic melt filter with the widest filtration surface in a single chamber, and with only two screens compared to the same filtration surface offered by competitors.

GEM was created from the combination of two of our best ideas: the proven reliability of RAS and the dual filtration concept of ERA.

Two Ø600 or Ø700 mm filters, two scrapers, two independent valves: up to 7,592 cm² of active filtration surface, for processing large volumes, even with highly contaminated materials.

One machine, two chambers, superior performance.

GEM is our answer to the most ambitious challenge: increasing hourly productivity without compromising the final quality.

All of this with just two screens, minimal waste, and low operating costs.

Because large-scale recyclers need technology that delivers consistently — and always stays ahead.

Double filtration chamber:

GEM has two independent filtration chambers, doubling hourly production compared to traditional filters.

Laser or punched screen options:

Laser screen: 60 / 70 / 80 / 100 / 120 / 150 / 200 / 250 / 300 micron

Punched screen: 400 / 500 / 600 / 800 / 1000 / 1500 / 2000 micron

Double discharge valve:

GEM doubles the discharge outlets for contaminants as well.

Choosing the right filter

Selecting the correct filter is crucial to get the most out of GEM.

60–300 micron

400–2000 micron

Filter size

- Ø600mm – 5552cm²

- Ø700mm – 7592cm²

Laser screen

- micron: from 60 to 300

- mesh: from 230 to 50

Punched screen:

- micron: from 400 to 2000

- mesh: from 40 to 10

Filtered materials

- PP / LDPE / LLDPE / HDPE/ PS / EPS / XPS / ABS / PVB²

How GEM works

GEM doubles the filtration surface thanks to two active screens, where melt flows in parallel.

Each flow is managed by its own scraper and dedicated discharge valve, ensuring maximum efficiency even at high throughputs and with difficult materials.

The blades scrape the impurities retained by the screen, while the scraper collects the contamination and directs it to the discharge device.

When the preset threshold is reached, the scraper rotates at the set speed and discharges only at the end of a full cycle, ensuring a precise and clean operation.

Continuous mode

In case of high contamination, the scraper rotates constantly at low speed, and the valve—controlled by an intelligent timer—opens only when necessary.

Two independent filtration lines, one perfectly coordinated process. No compromise between quality and continuity.

Discharge mode and filtration level can also be customized depending on the material being processed.

Thanks to automated control via touch screen, the operator can set:

- Operating mode (continuous or pressure)

- Discharge timing

- Working temperature

Why GEM is the right choice for high throughput and high contamination

Two chambers working in sync for maximum efficiency. Simultaneous double filtration – Optimized cycles, consistent output.

High flows, complex contaminants, clean results: GEM is designed for systems with high flow rates and critical materials to be processed.

Minimal spare part costs, only two screens required, reduced initial investment.

Easy access, quick spare parts, tutorials. Minimize downtime with on-demand instructions and tutorials.

GEM can be fully adapted to your line and production requirements: throughput, filtration levels, and material-specific options.

Like every FIMIC melt filter, GEM works fully automatically, managed directly through a touch panel.

See the difference

Because a good result is not only visible

It can be touched, measured, and weighed.