Nordson BKG and FIMIC Launch Integrated High-Throughput Polyolefin Recycling Solutions at K 2025

Münster, NRW, Germany / Carmignano di Brenta, Italy – October 2, 2025 – In response to the rapidly growing demand for high-capacity polyolefin recycling systems, Nordson BKG GmbH, part of Nordson Corporation’s (Nasdaq: NDSN) Polymer Processing Systems division, and FIMIC S.r.l., have announced a strategic collaboration to deliver fully integrated solutions capable of processing 4.0 to 6.0 tons per hour of post-consumer plastics.

The joint solutions address key industry challenges, including material variability, filtration limitations, and costly downtime. By integrating Nordson’s advanced gear pumps, valves, and underwater pelletizing systems with FIMIC’s high-performance filtration units the systems ensure consistent pressure, superior filtration, and pellet homogeneity — even at high throughputs and high level of automation.

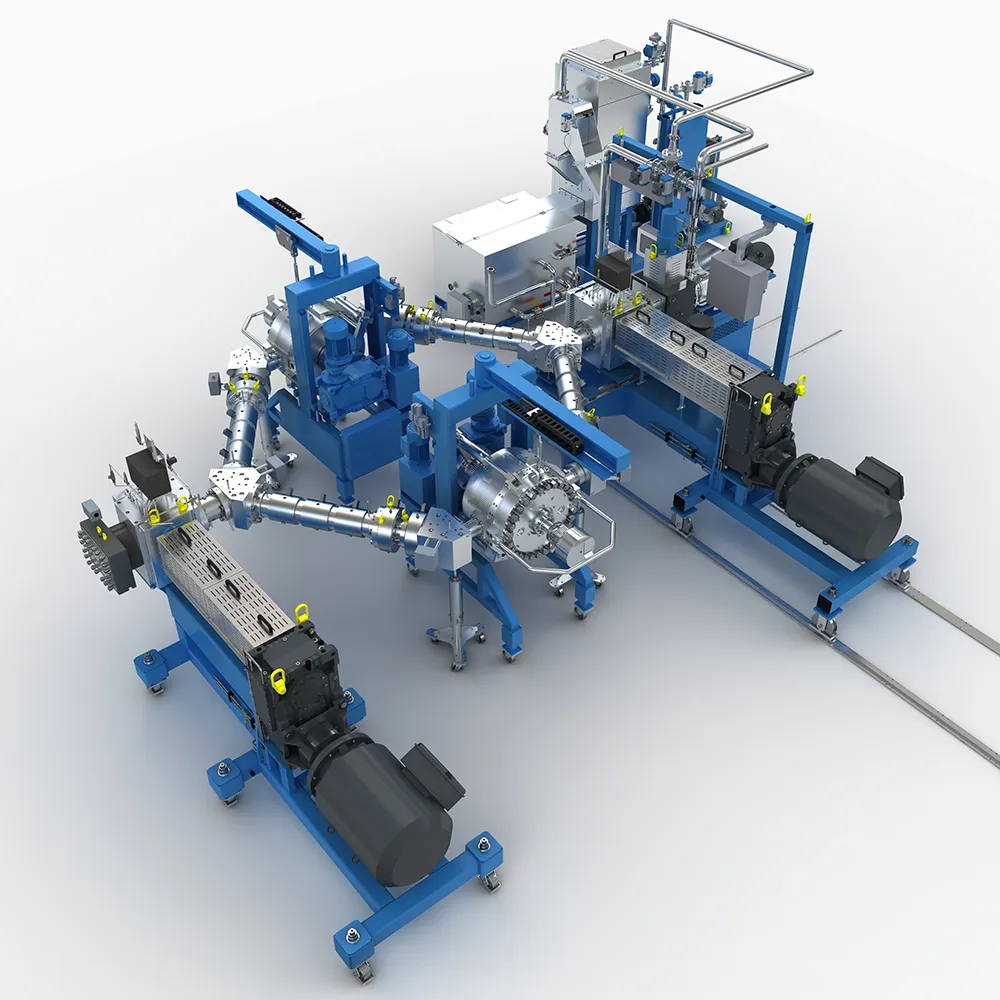

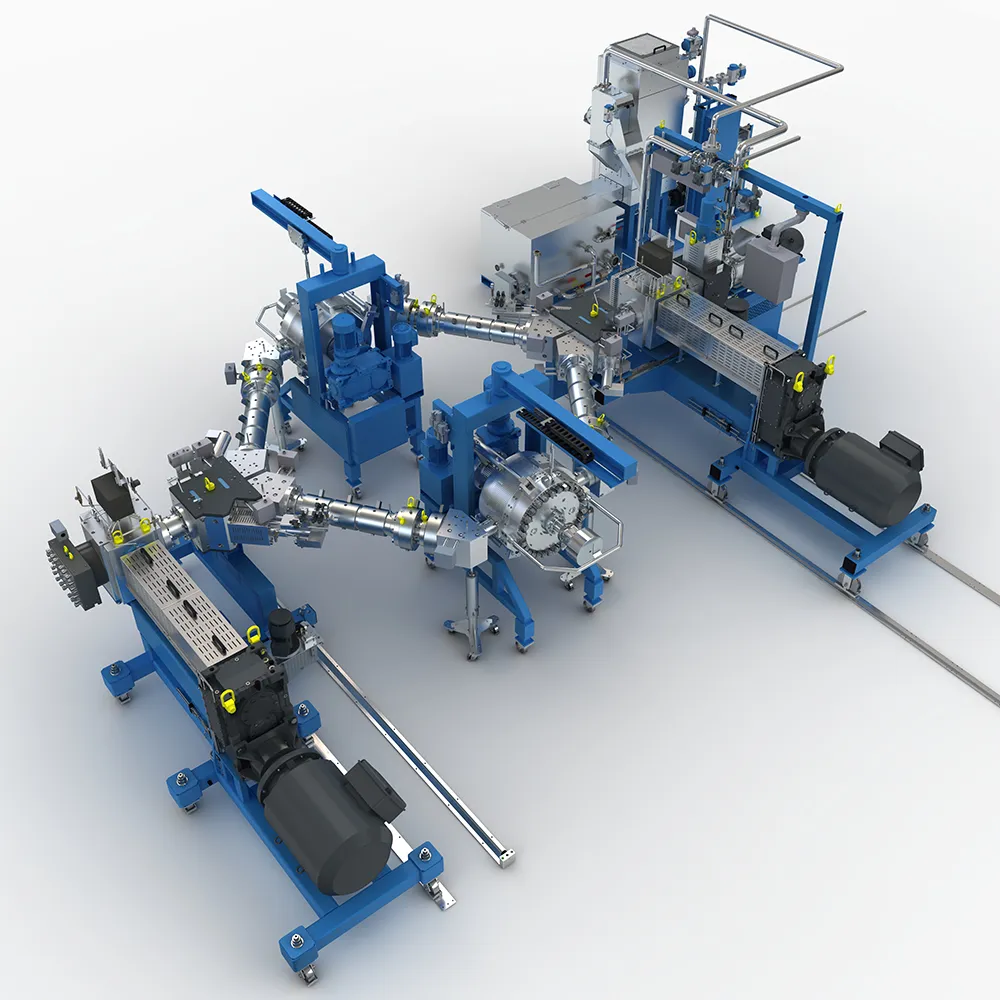

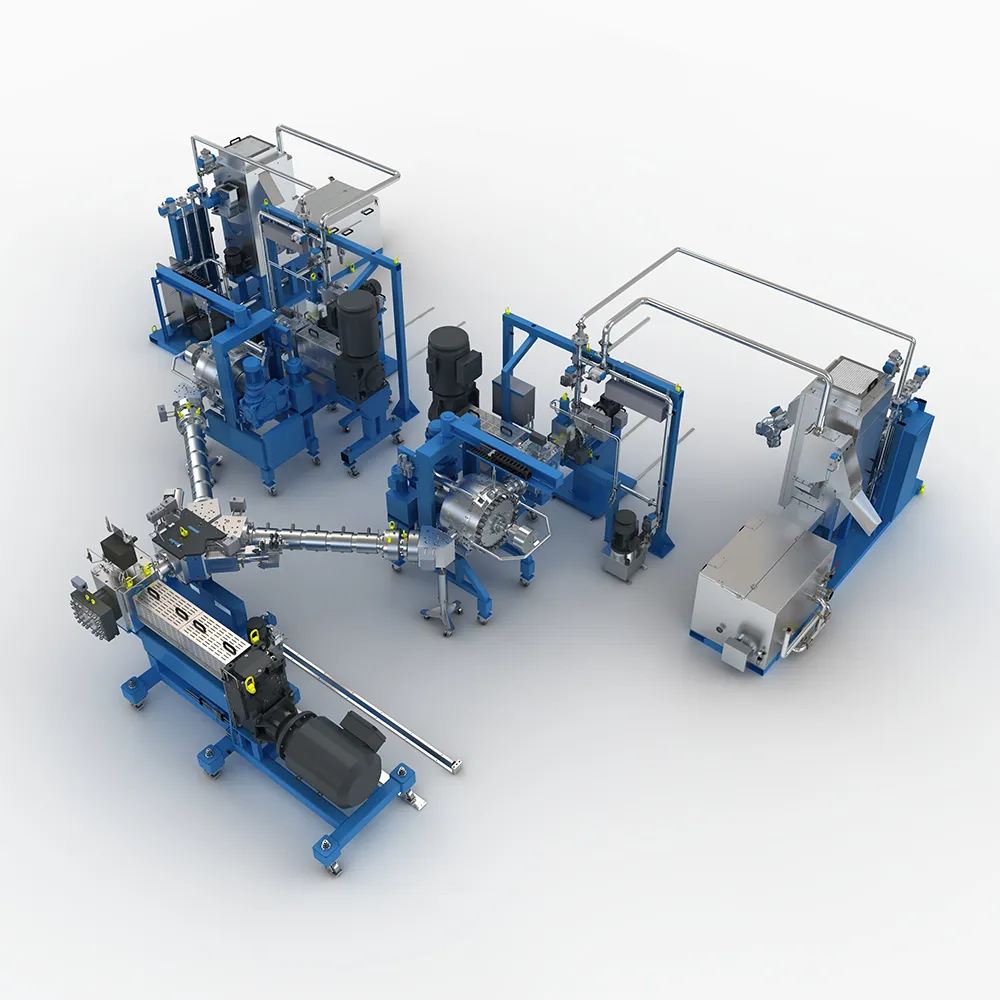

To meet the diverse and evolving demands of high-capacity polyolefin recycling, Nordson BKG and FIMIC have engineered a modular system architecture offering exceptional operational flexibility. The solution is available in three distinct configurations — DO (Discontinuous Operation), CO (Continuous Operation), and CFO (Continuous Flexible Operation) — each tailored to specific production environments, throughput goals, and maintenance strategies. This versatility empowers recyclers to optimize performance, minimize downtime, and maintain consistent product quality across varying operational scenarios.

- DO-Line (Discontinuous Operation): A cost-effective solution requiring a complete line shutdown during screen changes on the FIMIC melt filter.

- CO-Line (Continuous Operation): Features dual diverter valves that allow screen changes on one filter while the other remains in operation, maintaining up to 75% throughput during transitions.

- CFO-Line (Continuous Flexible Operation): The most advanced configuration is equipped with two underwater pelletizers. This setup enables one line to remain fully operational while the other undergoes maintenance, ensuring uninterrupted production. Smaller equipment reduces investment and spare part cost for gear pumps and underwater pelletizing systems.

Key Features of the Integrated System:

- Complete Solution: Seamless integration from twin-screw adaptor flange to underwater pelletizer.

- High Performance: Minimum throughput of 4 t/h with filtration precision down to 100–150 μm.

- Automation & Efficiency: Intelligent pump control, modular system design, and minimal operator involvement work together to maximize performance and lower Total Cost of Ownership (TCO). Meanwhile, the fully automated, intelligent venting process ensures consistent product quality—even during filter changes—by eliminating defects.

- Thermal Management: Innovative design strategies, including mobile components and thermal elongation adaptors, maintain system stability under high-temperature conditions for high-capacity lines.

A key advantage of this partnership is the “one face to the customer” approach. By eliminating interface challenges and streamlining communication, Nordson and FIMIC ensure seamless integration and simplified project execution.

At Nordson BKG’s technical center in Münster, customers can experience firsthand how seamlessly Nordson BKG and FIMIC components integrate to deliver a unified solution.

This joint innovation reflects both companies’ commitment to advancing sustainable, high-efficiency recycling technologies for the circular plastics economy, enabling recyclers to meet stringent quality standards while scaling operations efficiently.

Visit Nordson BKG in Hall 9, booth no. D09, and FIMIC in booth no. D18 at K 2025.

About FIMIC Srl.

FIMIC Srl. is a leading manufacturer of self-cleaning coarse PCR melt filtration systems for the plastics recycling and extrusion markets. Focusing on innovation and sustainability, FIMIC is dedicated to providing customers with cutting-edge solutions for effective and efficient melt filtration. FIMIC’s state-of-the-art technology and customer-focused approach have positioned them as a trusted partner in the global plastics industry.

To learn more, visit www.fimic.it or LinkedIn / Facebook

About Nordson BKG GmbH

Nordson BKG GmbH is part of Nordson’s Polymer Processing Systems division. Nordson BKG GmbH provides customers with engineered components, homogenize, filter, meter, and give shape to plastic. Nordson Corp. leverages the collective plastics industry experience from strategic acquisitions to offer a uniquely broad portfolio of industry-leading technologies. Nordson delivers a full range of precision melt stream products — from filtration systems, pumps, and valves to pelletizing systems and pyrolytic cleaning ovens to meet the constantly evolving needs of the polymer industry.

Nordson provides customers with local technical sales, service, and remanufacturing capabilities through sales organizations and regional manufacturing. To learn more, visit www.nordsonpolymerprocessing.com, LinkedIn or Facebook.

About Nordson Corp.

Nordson Corp. is an innovative precision technology company that leverages a scalable growth framework through an entrepreneurial, division-led organization to deliver top-tier growth with leading margins and returns. The Company’s direct sales model and applications expertise serve global customers through various critical applications. Its diverse end market exposure includes consumer non-durable, medical, electronics, and industrial segments. Founded in 1954 and headquartered in Westlake, Ohio, the Company has operations and support offices in over 35 countries. Visit Nordson at www.nordson.com, Twitter or Facebook.

DO-Line (Discontinuous Operation)

CO-Line (Continuous Operation)

CFO-Line (Continuous Flexible Operation)